SILVERPHOS 15 (BCuP-5)

NOMINAL COMPOSITION

Copper 80.0% ± 1.0

Phosphorus 5.0% ± 0.2

Silver 15.0% ± 0.5

Other Elements, Total 0.15% Max

PHYSICAL PROPERTIES

Color

Solidus

Liquidus

Recommended Brazing Temperature

Density (lbs./in3)

Specific Gravity

Electrical Conductivity (%IACS)

Electrical Resistivity (Microhm-cm)

Gray

1190°F (643°C)

1475°F (801°C)

1525-1575°F (829-857°C)

0.31

8.44

9.90

14.4

USES

Silverphos 15 was developed primarily for use on copper, but its use has extended to other nonferrous copper base alloys. It is used extensively on refrigeration units, air conditioning apparatus, electrical conductors, copper and brass pipe fittings, and other copper and brass equipment.

BRAZING CHARACTERISTICS

Silverphos 15 is a copper rich, filler metal that is self-fluxing on copper by virtue of its phosphorus content. The self-fluxing property of this filler metals is effective on copper only. With copper-base alloys, such as brass or bronze, the joints should be fluxed. Silverphos 15 should not be used on nickel-base and iron-base alloys, as the phosphorus reacts with the nickel or iron to form brittle compounds at the interface of the joints. Silverphos 15 has a strong tendency to liquate (separation into low and high melting constituents) if heated slowly through its melting range, as normally occurs in furnace brazing. This results in leaving a “skull” of un-melted alloy behind which may be objectionable from the standpoint of appearance. In furnace brazing it is preferable to pre-place the alloys inside the joint where the skull is not visible. Normally the corrosion resistance of Silverphos 15 is of the same order as copper, but under certain conditions it may corrode more rapidly. Silverphos 15 should not be used where the joints are exposed to sulfur compounds, especially in gasses or oils at temperatures above normal room temperature. As the corrosion by sulfur is cumulative, even very small percentages will eventually cause failure of the joint by disintegration. Exposure to pressured steam can also result in accelerated corrosion.

PROPERTIES OF BRAZED JOINTS

The properties of a brazed joint are dependent upon numerous factors including base metal properties, joint design, metallurgical interaction between the base metal and the filler metal.

SPECIFICATIONS

Silverphos 15 alloy conforms to: Unified Numbering System (UNS) C55284 and American Welding Society (AWS) A5.8/A5.8M BCuP-5

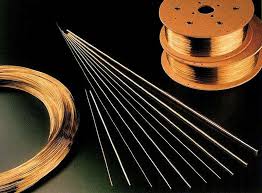

AVAILABLE FORMS

Wire, engineered preforms, specialty preforms per customer specification, powder and paste